Ethanol extraction is a widely employed technique for separating and purifying active compounds from plant materials. This method utilizes ethanol (alcohol) as a solvent to extract target compounds from raw materials, yielding purer products. Ethanol extraction finds extensive applications in pharmaceutical preparation, natural product purification, as well as the manufacturing of flavors and fragrances.

Pre-stored Ethanol

Recover ethanol. After recovery, the ethanol can be recycled.

Products Required:

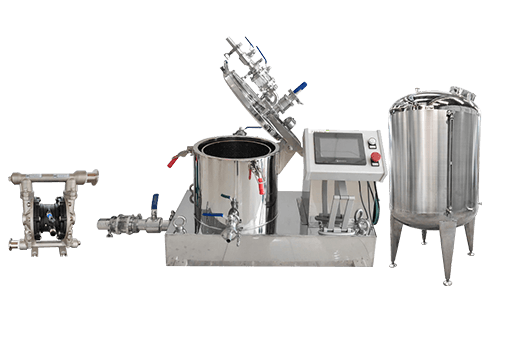

diaphragm pump

Stainless steel liquid tank

Refrigeration Ethanol

Ethanol solvent refrigeration temperature -40 ~ -80℃

Products Required:

Diaphragm pump

Refrigeration tank

Extraction

Low temperature extraction of 98% cannabinoids

Products Required:

Diaphragm pump

Extraction centrifuge

Insulated liquid storage tank

Filter

Remove most vegetable oils, waxes and impurities from the extraction solution

Products Required:

Diaphragm pump

Secondary filter

Insulated liquid storage tank

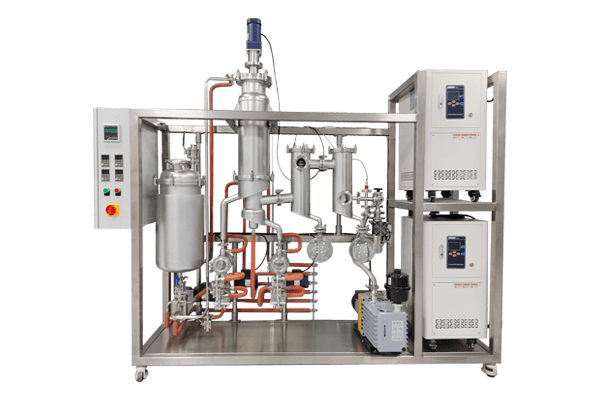

Falling film evaporator

Can evaporate and recover 90%~95% ethanol solvent

Products Required:

Falling film evaporator

Chiller

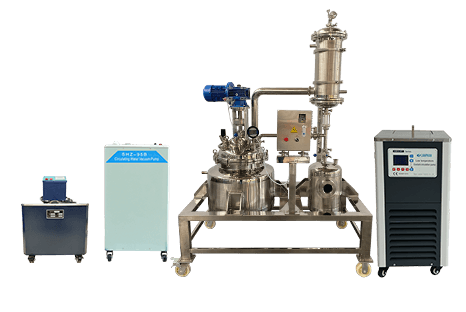

Decarboxylation

Recover residual ethanol solvent, natural cannabinoid carboxylic acid (such as THC a, cannabidiol a), and produce simple cannabinoids (such as THC, cannabidiol) and CO2 gas by heating

Products Required: Stainless steel decarboxylation reactor,High temperature oil bath,Vacuum pump,Chiller.

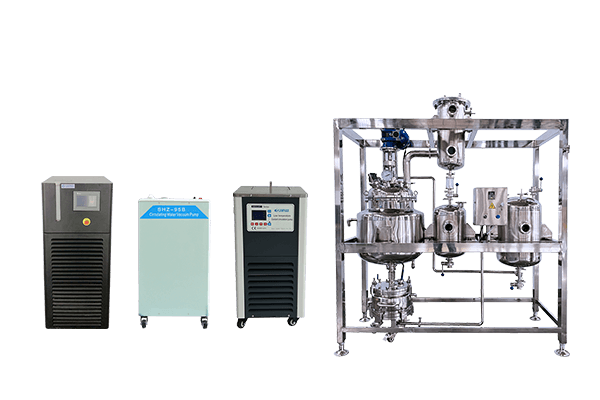

Crystallization

Obtain pure CBD crystals and separate the THC mixture

Products Required:

Crystallization reactor

high and low temperature

Vacuum pump

Chiller

Drying

Dry CBD crystals and remove residual solvents

Products Required:

Vacuum drying oven

Rotary vane vacuum pump