How does industrial freeze drying work?

The principle of industrial freeze-drying involves freezing the material first, then removing the moisture by turning the ice directly into water vapor in a vacuum. This process has three main steps:

1.Freezing: Cool the material below its freezing point to turn the moisture into ice.

2.Sublimation: In a vacuum, the ice turns directly into water vapor and leaves the material.

3.Drying: Remove any remaining moisture by raising the temperature slightly.

How long does industrial freeze dryer take?

The time it takes for an industrial freeze dryer to complete a cycle depends on several factors, including the type of material, its volume, moisture content, and the specific freeze-drying process used. Typically, the entire process can range from a few hours to several days. Smaller batches with lower moisture content generally finish faster, while larger volumes or higher moisture levels might require more time.

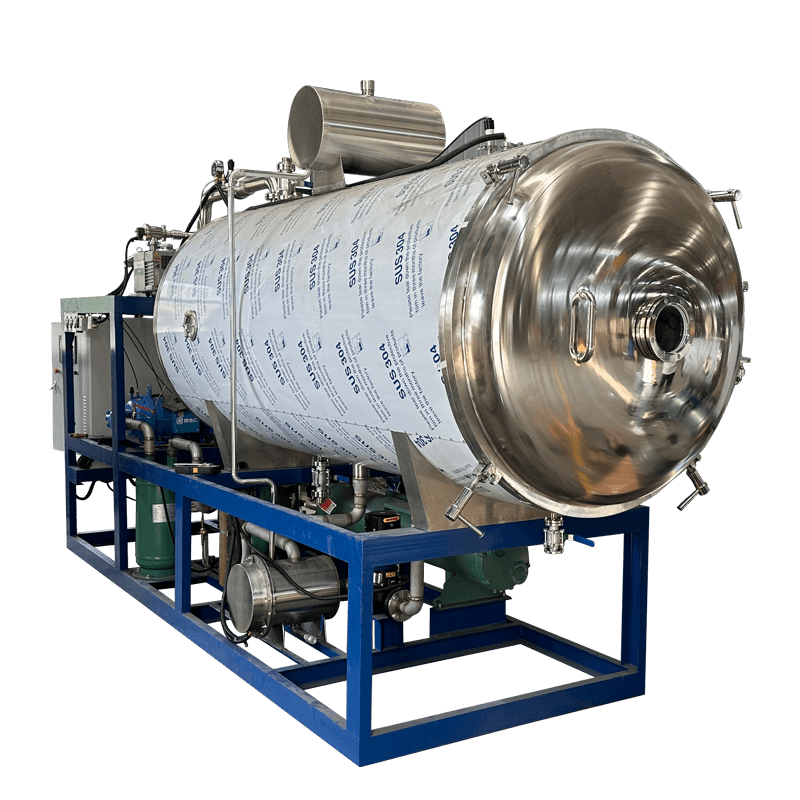

Industrial Freeze Dryer

- Input quantity(kg/batch):10-500

- Usable shelf area(m2):1.1-50

- Shelf working temperature (℃):-50~60℃

- Temperature difference of shelf :±1℃

- Condenser lowest temperature:-50~-65℃

- Defrost method:Spray and immersion