How to Make Tablets from Powder? A Simple Guide

Tablets are a convenient way to take medications, supplements, or other powdered substances. How to make tablets from powder? It’s a fascinating process that’s quite easy to do at home with the right tools and materials. Let’s dive into the step-by-step guide to making tablets from powder.

Why Make Tablets from Powder?

Making tablets from powder offers many advantages. Tablets are easy to store, handle, and dose. They have a longer shelf life than liquid forms and are portable, making them convenient for travel. Learning how to make tablets from powder can also save you money and give you control over the ingredients and dosages.

Materials Needed

To get started, you’ll need a few basic materials:

- Powdered substance (medication, supplement, or herbal powder)

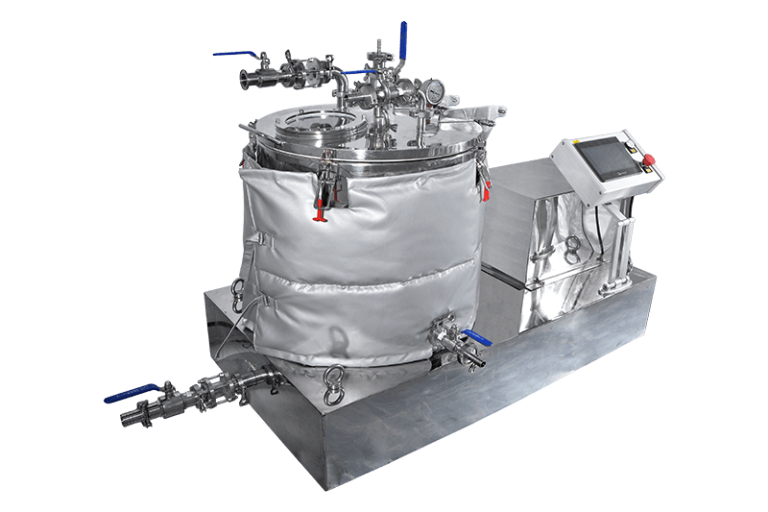

- Tablet press (manual or automatic)

- Binding agent (like starch, gelatin, or cellulose)

- Lubricant (magnesium stearate or talc)

- Measuring tools (scale, spoons)

- Mixing bowl

- Tablet molds (if not using a press)

Step-by-Step Guide

1. Prepare the Powder

How to make tablets from powder? The first step is to prepare your powder. Ensure it is finely ground. This is crucial because a uniform powder ensures even distribution of active ingredients in each tablet.

2. Add a Binding Agent

A binding agent helps the powder stick together. Common binding agents include starch, gelatin, and cellulose. Mix your powdered substance with the binding agent in a mixing bowl. The ratio can vary, but a typical starting point is 2-5% of the total weight of the powder.

3. Mix Thoroughly

Ensure the powder and binding agent are mixed well. This step is crucial for making uniform tablets. If the powder is not mixed well, some tablets might be too strong or too weak.

4. Add a Lubricant

Lubricants prevent the powder from sticking to the tablet press. Magnesium stearate or talc are commonly used. Use about 1% of the total powder weight. Mix it in thoroughly.

5. Measure the Dose

Carefully measure the amount of powder needed for each tablet. This ensures each tablet contains the correct dose. Use a precise scale for accuracy.

6. Compress the Tablets

Place the measured powder into the tablet press or molds. If using a manual press, apply even pressure to compress the powder into tablets. If using molds, fill them evenly and compress with a flat tool.

Troubleshooting Common Issues

How to make tablets from powder without issues? Here are some common problems and solutions:

- Tablets Crumbling: Increase the amount of binding agent.

- Tablets Sticking: Add more lubricant or clean the tablet press.

- Uneven Tablets: Ensure even mixing and consistent pressure.

Drying the Tablets

Once compressed, the tablets need to dry. Place them in a dry, cool area. If using a food dehydrator, set it to a low temperature. Ensure they are completely dry before use.

Storing Your Tablets

Store your tablets in an airtight container. Keep them in a cool, dry place. This prevents moisture from affecting the tablets and extends their shelf life.

Benefits of Homemade Tablets

Making your own tablets gives you control over the ingredients. You can avoid unwanted fillers and additives. It also allows you to customize dosages to suit your needs. Plus, it’s a cost-effective way to manage your supplements or medications.

Tips for Success

- Use High-Quality Powders: The quality of your powder affects the quality of your tablets.

- Maintain Clean Equipment: Clean equipment prevents contamination and ensures consistent results.

- Experiment with Ratios: Finding the right ratio of binding agent and lubricant can take some experimentation.

Safety Considerations

Always consult a healthcare professional before making tablets from medication powders. Ensure the dosages are correct to avoid any health risks. If using supplements or herbal powders, research their effects and proper dosages.

Conclusion

How to make tablets from powder? It’s a straightforward process that requires the right materials and careful attention to detail. With this guide, you can create your own tablets at home, tailored to your needs. Whether for health, convenience, or cost savings, making tablets from powder is a useful skill.

Ready to take your tablet-making skills to the next level? Explore advanced techniques and tips to perfect your homemade tablets! Keep reading to discover more about enhancing tablet quality and troubleshooting any issues you might face.