Freeze Dryer Machine: Preserve Your Food and Products with Ease

What is a Freeze Dryer?

A freeze dryer machine is a piece of equipment used to preserve food, pharmaceuticals, and more by removing water through lyophilization. It works by freezing the product, then reducing pressure to remove the moisture, leaving the product in a dry, stable form. This process retains the food’s nutritional value, flavor, and texture, making it perfect for long-term storage and emergency use.

Freeze Drying Process

- Freezing: The food is rapidly frozen under low temperature conditions, causing the water inside to form ice crystals.

- Reduced pressure: The frozen food is placed in a vacuum chamber, and the surrounding pressure is reduced, causing the ice crystals to convert into water vapor at a lower temperature.

- Water removal: The water vapor is drawn out by a vacuum pump, causing the water inside the food to change directly from a solid to a gas state, thus avoiding the loss of nutrients caused by water.

- Solidification: After pressure reduction and water removal, the water inside the food has been completely removed, resulting in a dry state.

Freeze Dryer Features & Benefits

Pharmaceutical Freeze Dryer

- Ease of Use: User-friendly design for hassle-free operation at home.

- Food Preservation: Retains nutrition and flavor, extending shelf life.

- Versatility: Processes various foods like fruits, veggies, meats, providing options.

- Space-Saving: Compact design for easy storage.

- Convenient Storage: Food doesn’t require refrigeration post-drying.

- Wide Application: Ideal for outdoor use, emergencies, homemade products.

- Quality Maintenance: Maintains food quality even after rehydration.

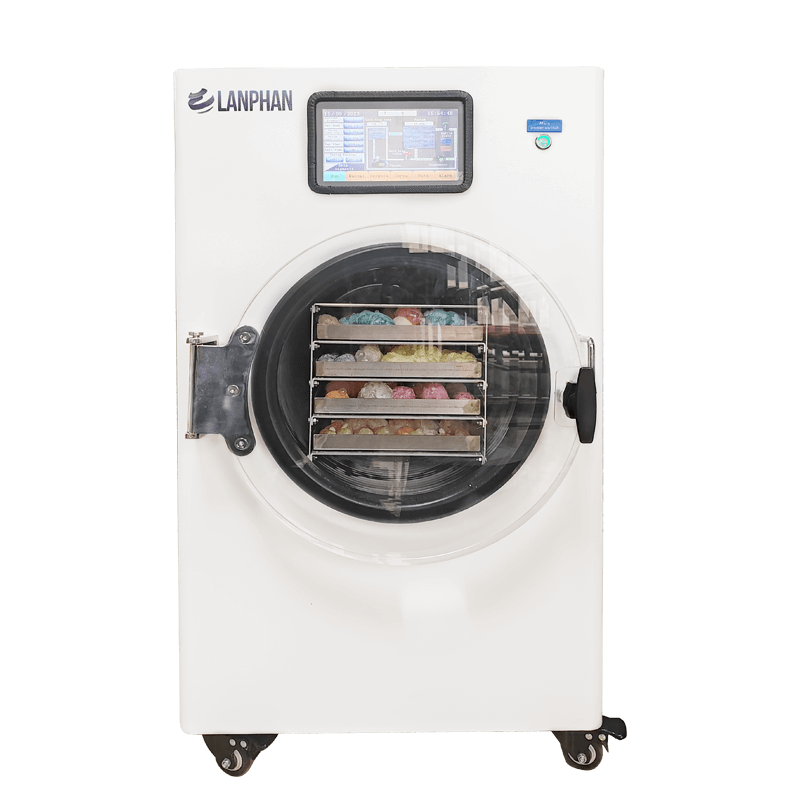

Home Freeze Dryer

- Ease of Use: User-friendly design for hassle-free operation at home.

- Food Preservation: Retains nutrition and flavor, extending shelf life.

- Versatility: Processes various foods like fruits, veggies, meats, providing options.

- Space-Saving: Compact design for easy storage.

- Convenient Storage: Food doesn’t require refrigeration post-drying.

- Wide Application: Ideal for outdoor use, emergencies, homemade products.

- Quality Maintenance: Maintains food quality even after rehydration.

Pilot Freeze Dryer

- Authentic Flavor: Preserves traditional taste.

- Texture Retention: Maintains ingredient texture.

- Nutrient Preservation: Retains nutritional value.

- Convenience: Easy to store and carry.

- No Additives: Typically additive-free.

- Extended Shelf Life: Longer preservation duration.

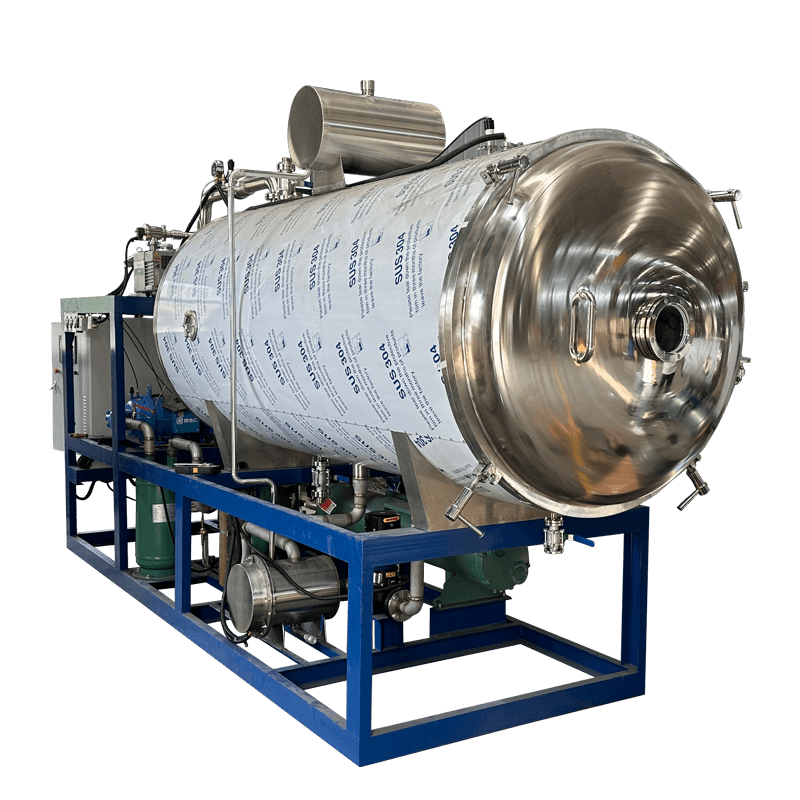

Industrial Freeze Dryer

- Large Capacity: Designed for high-volume processing, ideal for large-scale production.

- Energy Efficiency: Advanced technologies ensure energy savings without compromising performance.

- Automated Control: Sophisticated systems allow precise control over the entire freeze-drying process, ensuring consistent quality.

- Versatility: Capable of handling various tasks, including custom processing.

- Easy Maintenance: Modular design makes routine maintenance and repairs straightforward.

Product Comparison: Home vs. Industrial Freeze Dryer

| Feature | Home Freeze Dryer | Industrial Freeze Dryer |

|---|---|---|

| Cycle Time | 24-36 hours | 8-16 hours |

| Capacity | 5-10 lbs/batch | 50-200 lbs/batch |

| Energy Use | 1.2kW/h | 4.8kW/h |

| Best For | Family Use | Food/Biotech Production |

Why Choose Lanphan Freeze Dryers?

Our freeze dryer are engineered to deliver reliable and consistent performance. Designed with cutting-edge technology, our machines provide:

- Leading Freeze Dryer Manufacturers: Lanphan is recognized for reliable, high-quality freeze dryers.

- Tailored Solutions: Custom freeze-drying options for both home use and industrial applications.

- Global Reach: Serving customers worldwide with the best in freeze drying technology.

Whether you’re in the food industry, healthcare, or laboratories, our industrial autoclave machines ensure superior sterilization results with the utmost reliability.

Get Your Freeze Dryer Today!

Ready to start freeze drying at home or scale up your production? Contact us to learn more or get a quote for your freeze dryer machine.

Freeze Dryer Videos

Frequently Asked Questions (FAQ) About Freeze Dryer

What is a Freeze Dryer?

Freeze Dryer removes water via sublimation (ice→vapor) under vacuum and low temp, preserving structure and nutrients.

3 Steps:

1.Freezing: Rapid cooling (-40°C) solidifies water.

2.Primary Drying: Sublimation under vacuum, ice→vapor removed by condenser.

3.Secondary Drying: Heat breaks bound water bonds, final moisture <2%.

Uses: Food (coffee, fruits), pharma (vaccines), labs (bio-samples).

Advantage: No heat damage, porous structure, long shelf life.

Key Tech Terms: Sublimation, lyophilization, vacuum, condenser, bound water.

Are Freeze Dryers Worth the Investment? Here's the Reality

Freeze dryers deliver industry-leading food preservation, retaining 95-99% of nutrients and flavors for 25+ years – but their high initial cost ($2K-$5K+) creates decision paralysis. Here’s who benefits most:

- Homesteaders/preppers: Slashes long-term food costs. Retail freeze-dried meals cost $10-$15/serving vs. $1-$3/serving DIY

- Food entrepreneurs: Create premium shelf-stable products (coffee, herbs, camping meals) with 40-60% profit margins

- Gardeners/families: Only viable if preserving 100+ lbs/year or bulk purchases (e.g., 50 lbs of seasonal produce)

Smart Buyer Strategy

Test demand first: Many USDA-certified kitchens offer freeze-drying services ($1.50-$4/lb). Used commercial units (properly sanitized) can reduce startup costs by 50%.

How long does freeze drying take?

The freeze-drying process generally ranges from 24 to 48 hours, though timing varies based on material composition, sample thickness, and equipment specifications. Smaller batches or items with low moisture content may finish faster, while dense materials or large-scale operations often extend the cycle. Professional-grade systems optimize phase transitions between freezing and vacuum drying stages to preserve quality efficiently. For precise estimates, consult product-specific guidelines or industry specialists familiar with your project parameters.

Can I freeze dry liquids like soup?

Liquids including broths and soups can be freeze dried using shallow trays for optimal surface exposure. The process requires pre-freezing to solid state before vacuum dehydration, typically adding 3-5 hours to standard cycles. Results yield shelf-stable concentrates that retain original flavor when rehydrated. Note: High-fat content liquids may require cycle adjustments to prevent oil separation. Always conduct small-batch tests with your specific recipe.

Is a freeze dryer better than a dehydrator?

Freeze drying (lyophilization) preserves 95%+ nutrients with porous molecular structure, ideal for sensitive materials like probiotics. Dehydrators use heat (120-160°F) causing 20-40% nutrient loss through thermal degradation. While freeze-dried items maintain 25-year shelf life versus 1-5 years with dehydration, the process consumes 30-50% more energy. Commercial kitchens often combine both: freeze drying for high-value ingredients (berries/herbs), dehydrating for bulk items like jerky.